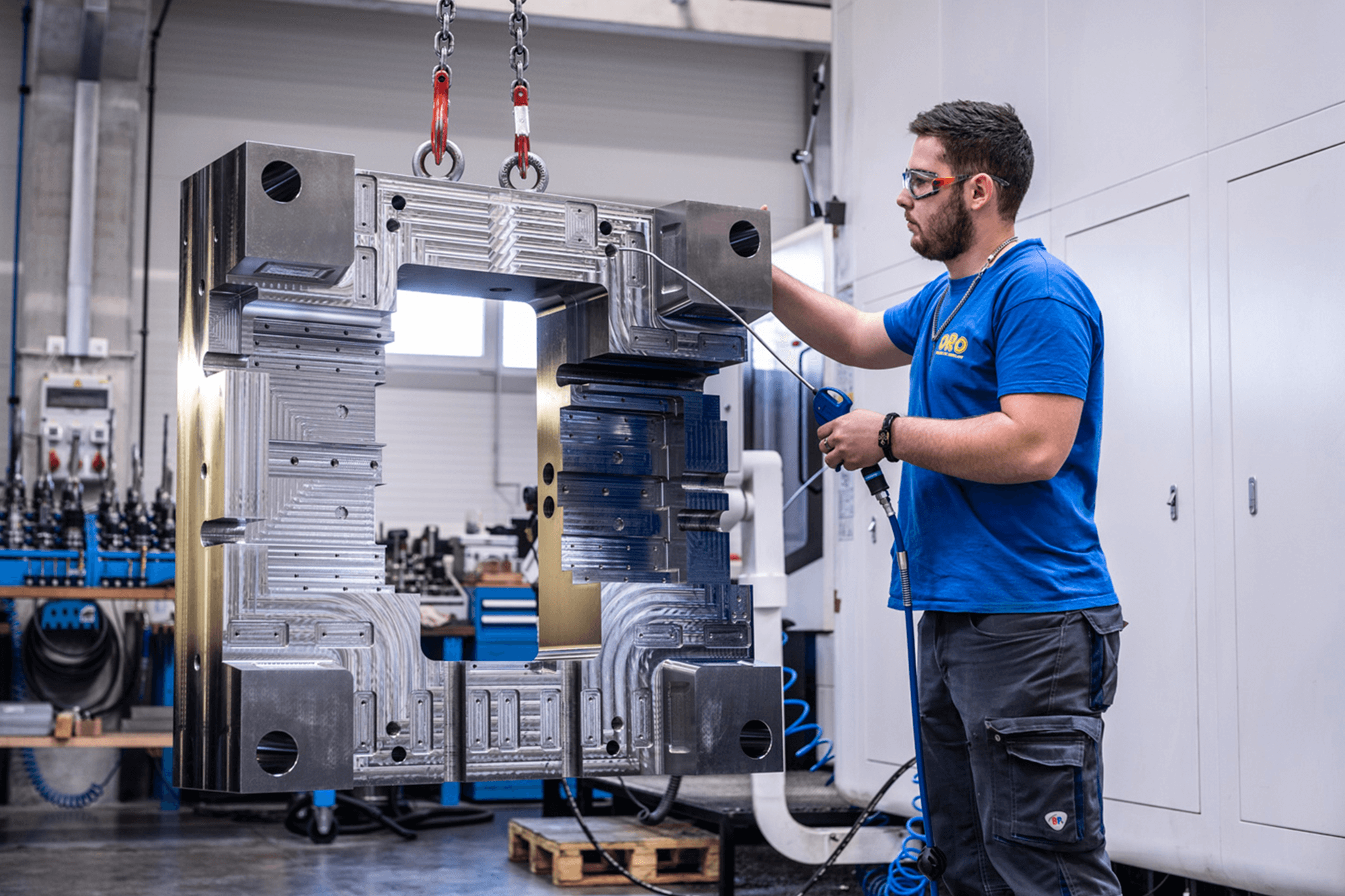

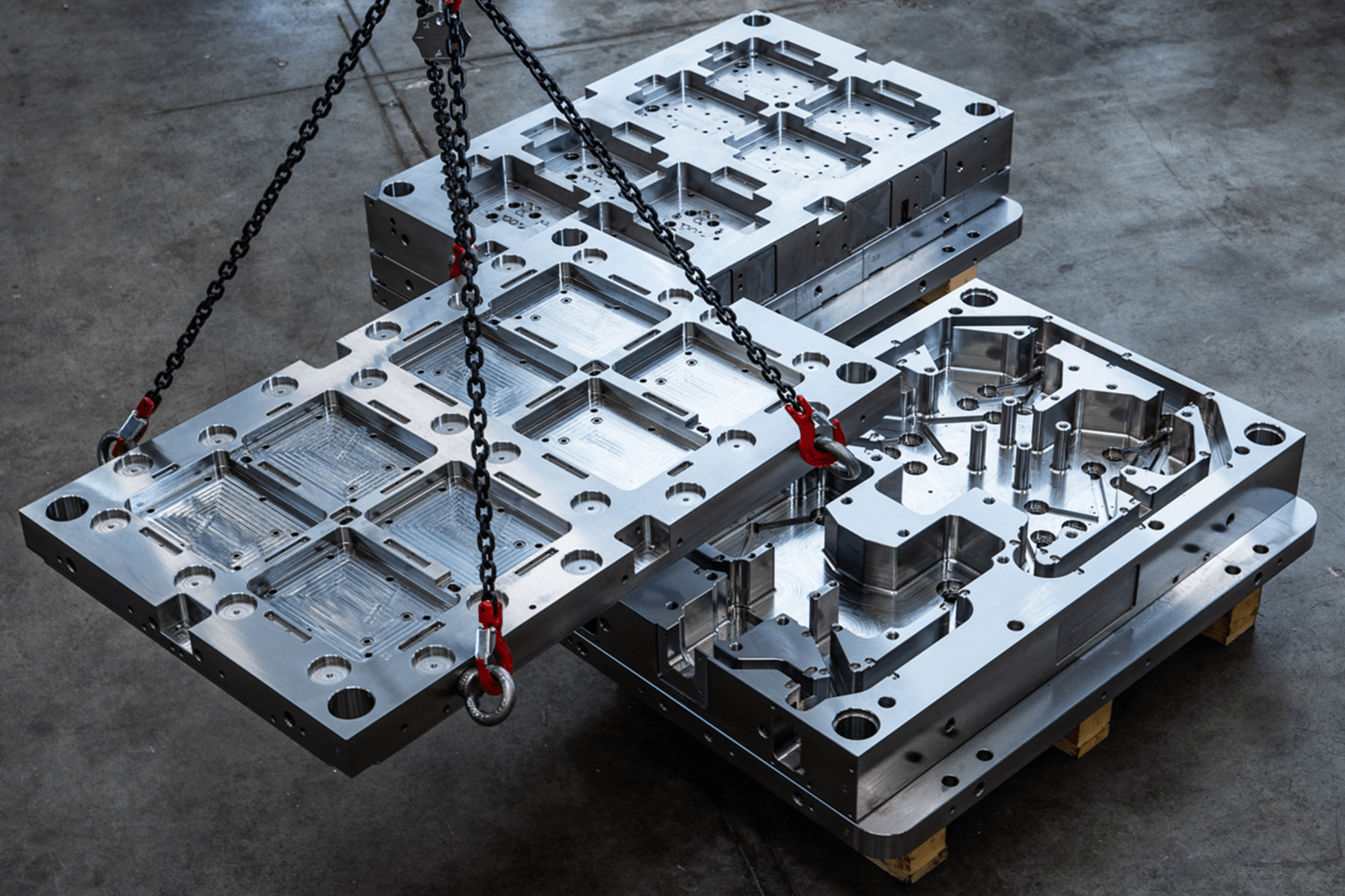

We specialize in the PRODUCTION OF MORE DEMANDING AND MORE PRECISE CNC 3-AXIS MACHINING AND 5-AXIS MACHINING of tooling plates and tool frames (2K, 3K and 4K) for different tool types.

Tools for plastic injection moulding

Pharmacy tools

Package tools

Multi-cavity moulds

Fine stamping tools

Die-casting tools and rubber

ABOUT THE COMPANY

In its 30-year practice the company has been recommended by the most demanding customers, mostly due to high-quality products and insignificant amount of faults and complaints.

OUR BUSINESS IS DISTINGUISHED BY

Meeting deadlines

Quick response to customer's demands

Assistance in solving construction challenges

70 % of our customers are from Germany

so the company has its own sales agent there.

INVESTMENTS

2017

Building a new air-conditioned production hall (800 m²) and purchasing six new CNC machining centres, three of which are intended for precision machining;

2019

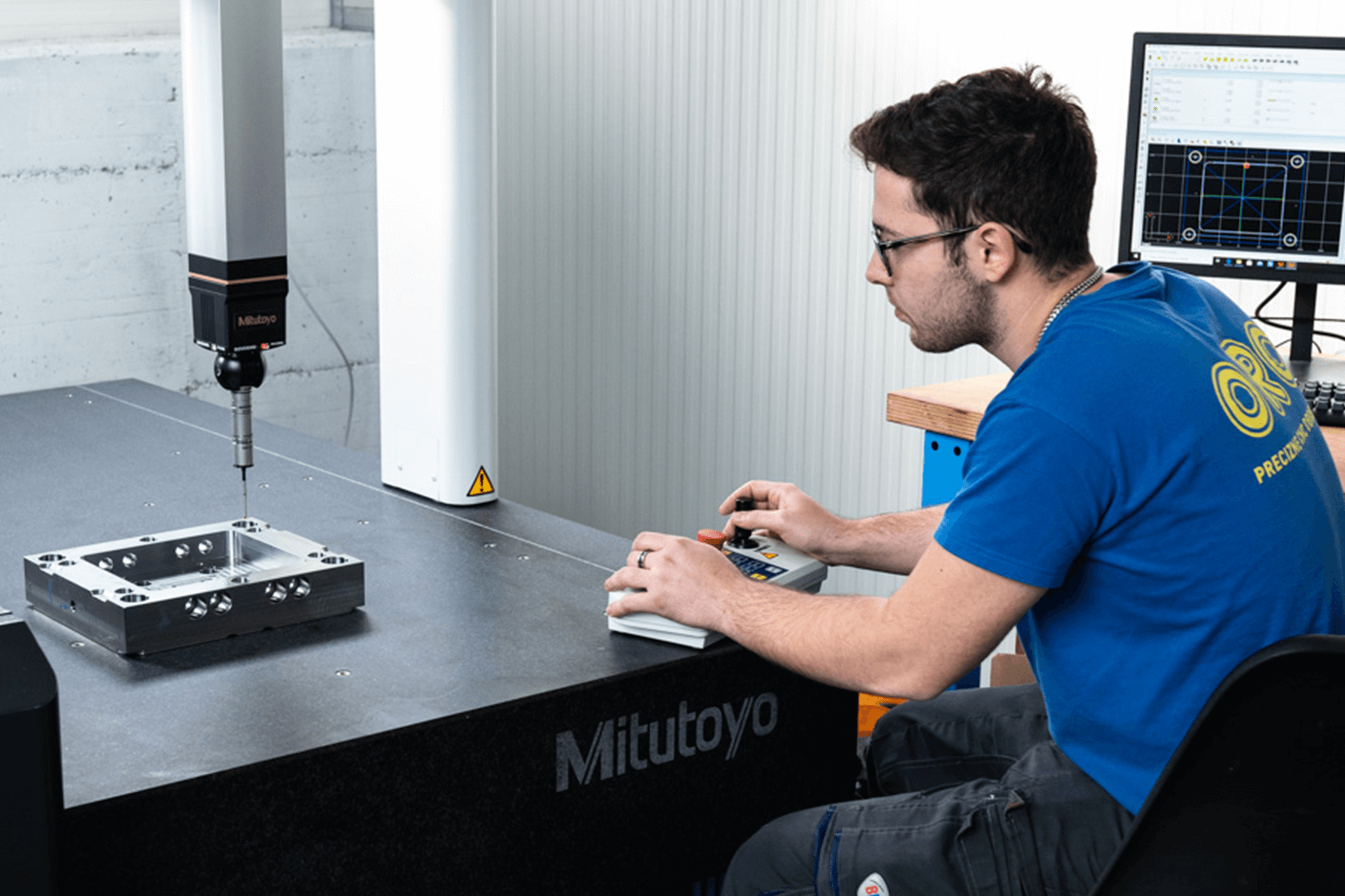

Purchasing a modern measuring machine Mitutoyo

2020

Purchasing a machining centre for Röders precision CNC machining.

2021-22

Building an additional production hall (730 m²).

2022

Purchasing a high-precision 5-axis CNC machining centre Axa

2023

Installation of a solar power plant on the roof of the ORO d.o.o. building under the European Cohesion Policy.

CERTIFICATES

EMPLOYEES

We are well aware that all of the above could not be achieved without an excellent team of workers. We strive to provide a well-organized and good working environment with positive atmosphere, appropriate payment for their services and stimulation. We furthermore encourage our employees to attend specialized education courses and training. This is the only way for the company to become successfully competitive on the market and follow the latest trends in toolmaking industry. Currently, our team has 17 employees and we are already planning to take on extra staff.

THE MISSION OF THE COMPANY

Our key objective is making sure our customers are satisfied and that is achieved by ensuring the highest level of quality. We excel in manufacturing demanding precision CNC machining which serves as a powerful support to the toolmaking industry and other industries as well. We adhere to corporate social responsibility and constantly strive for maximum satisfaction of all the relevant players in the business process: the customers, the employees and the company owners.

THE VISION OF THE COMPANY

The company will take on a leading role among the Slovenian manufacturers dealing with demanding precision CNC machining, particularly for toolmaking and pharmaceutical industry. Its position on the market will be further reinforced by excellence in our business operations. The achieved quality of our products will increase the level of trust we enjoy with our customers and make it possible for us to expand to new markets.

PRODUCTION PROGRAMME

CNC 3-AXIS HIGH PRECISION MACHINING

CNC 3-axis high precision machining of tooling plates, tool frames and forming plates in a high precision machining centre Röders, providing precision machining with a tolerance of 0.005 mm.

Workpiece dimensions:

1000 mm x 800 mm, weight up to 2000 kg.

CNC 3-AXIS MACHINING

Fine and rough 3-axis CNC machining of tooling plates, tool frames and forming plates.

Workpiece dimensions:

2200 mm x 1200 mm, weight up to 4000 kg.

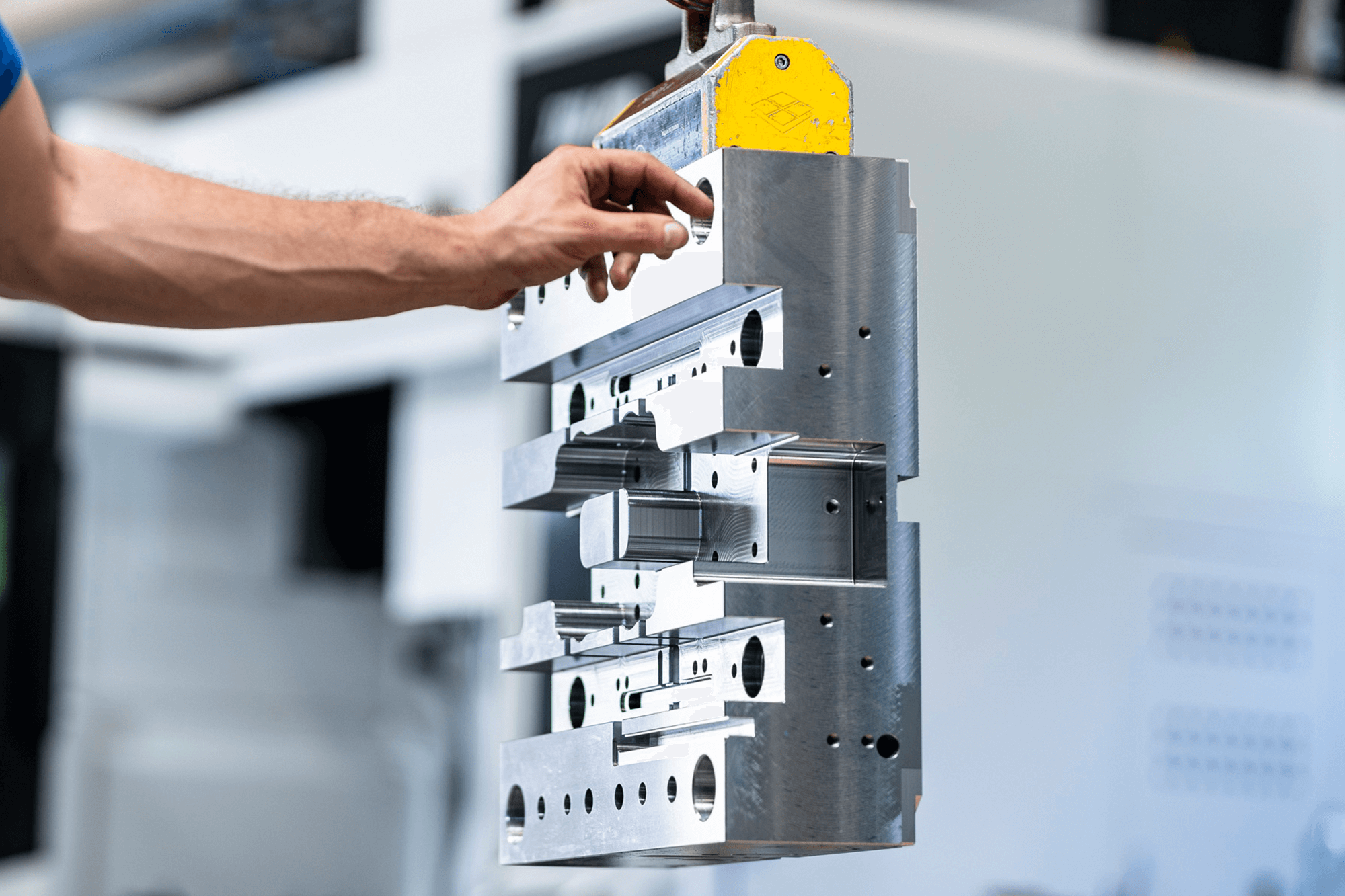

CNC 4-AXIS AND 5-AXIS MACHINING

CNC 4-axis and 5-axis machining of tooling plates, tool frames and forming plates.

Workpiece dimensions:

1000 mm x 800 mm, weight up to 2000 kg.

DEEP DRILLING

Deel drilling of cooling channels and heater holes and 4-axis less demanding CNC machining of tooling plates from the side.

Workpiece dimesions:

1200 mm x 1000 mm, weight up to 3000 kg

MEASUREMENTS

Measurements are made on a 5-axis precision measuring machine Mitutoyo for our own production and according to customer’s order.

MACHINERY

3-osni visoko precizni HSC CNC obdelovalni center Röders RXU 1001:

1000 mm x 810 mm x 500 mm,

weight up to 2000 kg

3-axis CNC portal machining centre:

2200 mm x 1200 mm x 780 mm,

weight up to 3500 kg

3-axis CNC portal machining centre:

1600 mm x 1200 mm x 700 mm,

weight up to 4000 kg

3-axis HSC CNC portal machining centre:

1200 mm x 800 mm x 700 mm,

weight up to 2500 kg

3-axis CNC machining centre:

1600 mm x 820 mm x 700 mm,

weight up to 2000 kg

3-axis CNC machining centre:

1050 mm x 570 mm x 510 mm,

weight up to 2000 kg

4-axis horizontal CNC machining centre:

1200 mm x 1000 mm x 500 mm,

weight up to 3000 kg

5-axis CNC machining centre:

1000 mm x 800 mm x 500 mm,

weight up to 2000 kg

5-axis CNC machining centre:

600 mm x 450 mm x 500 mm,

weight upt to 1000 kg

5-axis 3D coordinate measuring machine Crysta-apex S7106 with a scanning head:

1005 mm x 705 mm x 605 mm

5-axis high precision HSC CNC machining centre AXA:

1200 mm x 1200 mm x 500 mm

weight up to 2.500 kg

CONTACT

COMPANY INFORMATION

Neverke 68

SI-6256 Košana

Slovenija

VAT ID number: SI11911638

Registration number: 8222363000

IBAN: SI56 1010 0005 6852 277

SWIFT: BAKOSI2X

BANK: Banka Intesa Sanpoalo d.d.,

IBAN: SI56 2900 0005 6788 340

SWIFT: BACXSI2

BANK: UniCredit Banka Slovenija d.d.,

IBAN: SI56 0294 5026 2764 108

SWIFT: LJBASI2X

BANK: Nova Ljubljanska banka d.d.